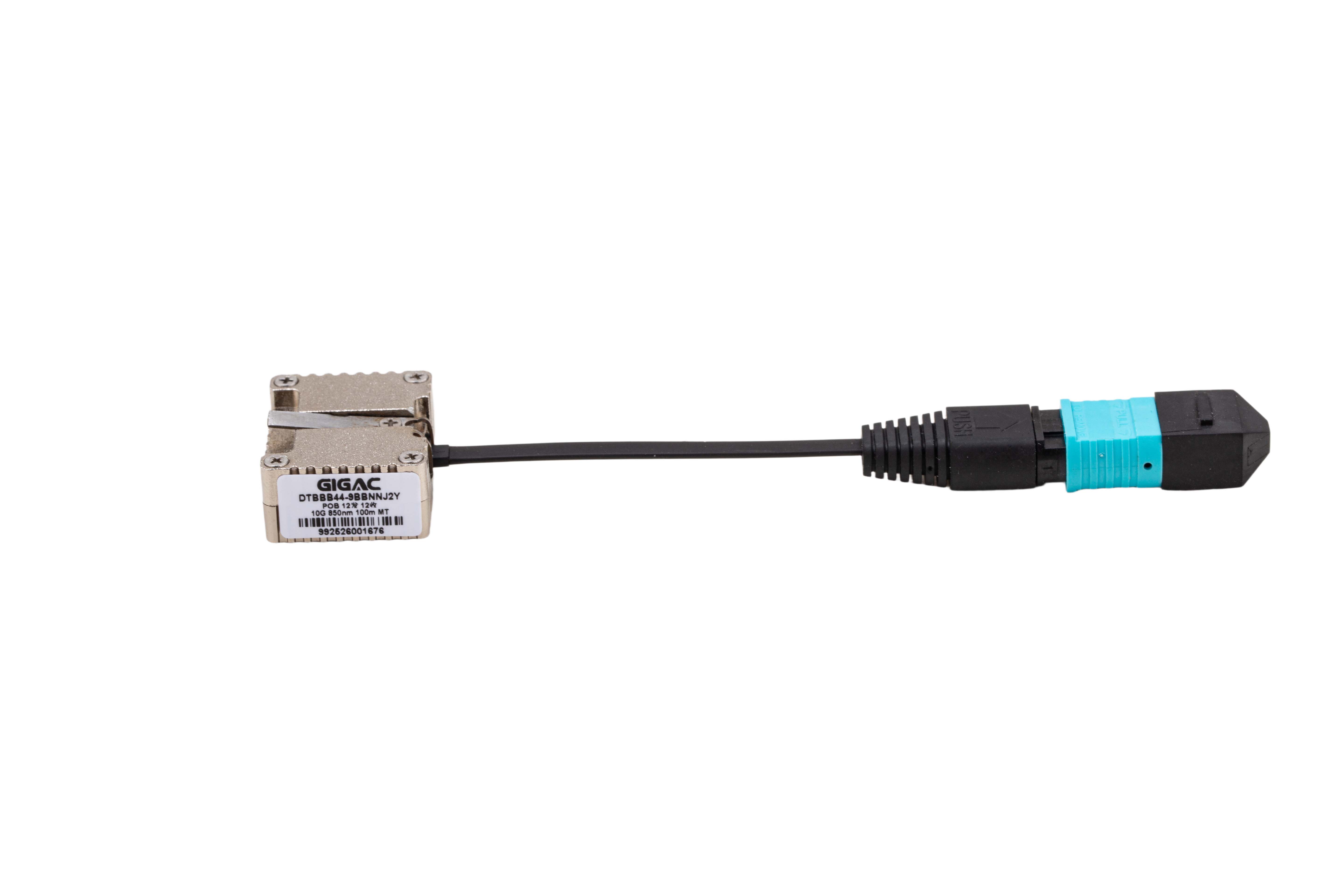

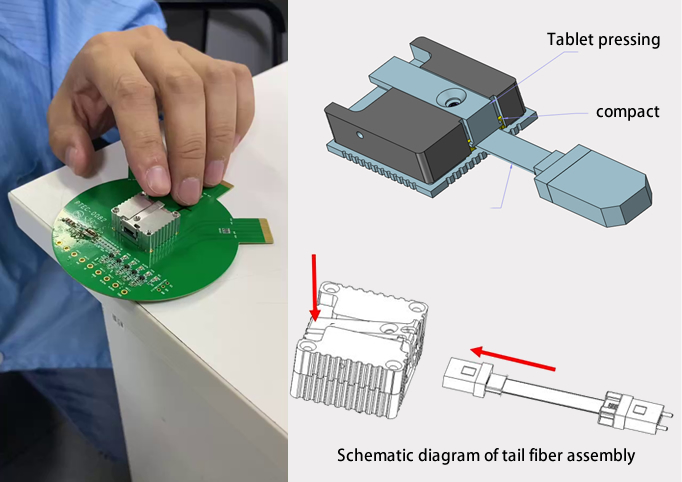

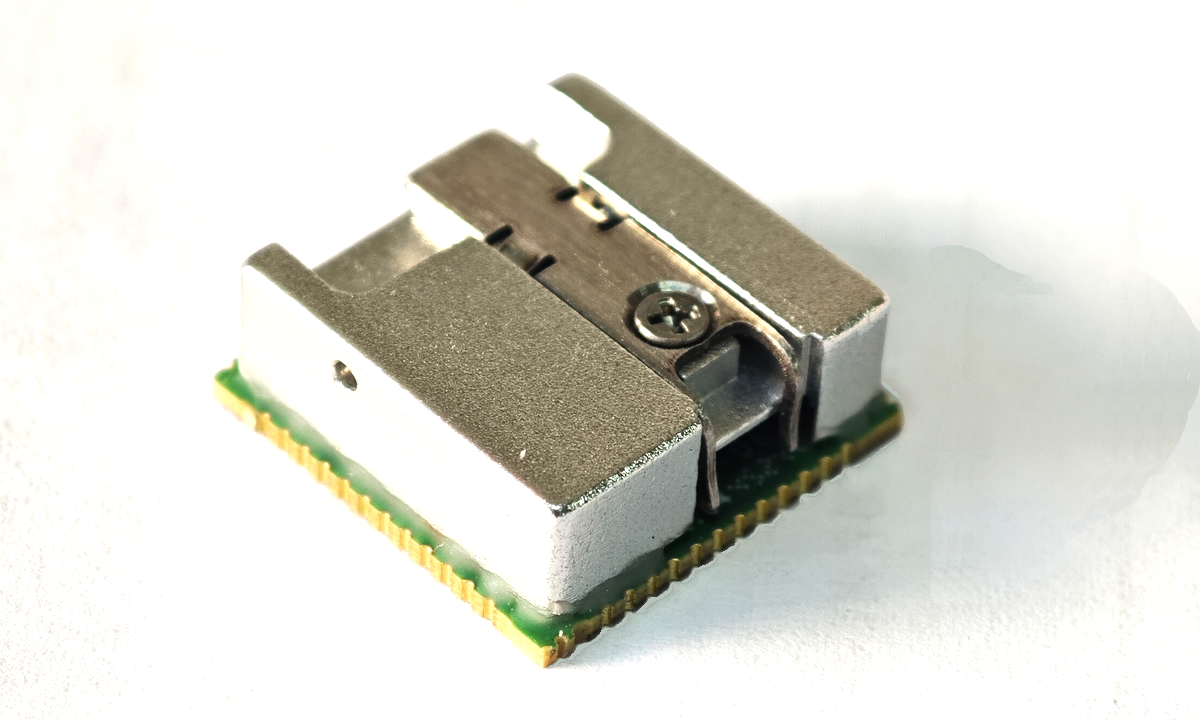

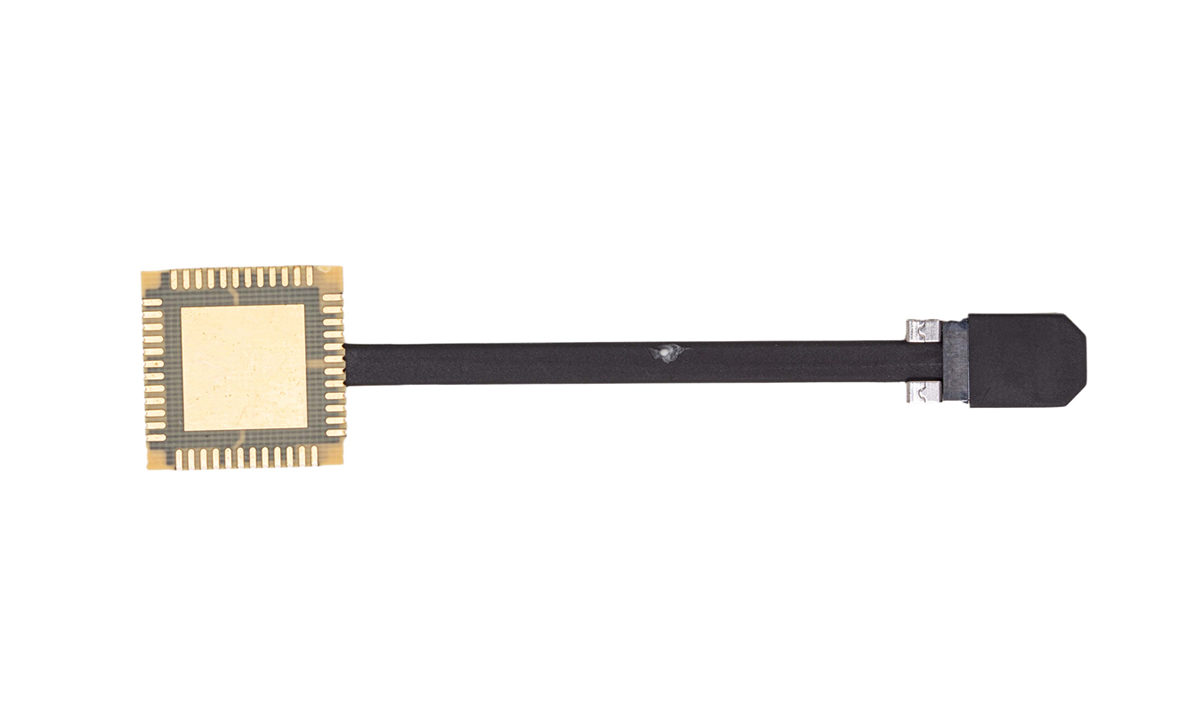

Inspired by the gecko's broken tail, Xinrui Technology's R&D team creatively developed a product that separates the parallel module from the fiber. After two years and millions of dollars in investment, they successfully developed a product with separate parallel modules and fiber pigtails. The Gecko Structure, a mythical Chinese beast, represents the purest of the nine dragon sons. The project leader named this product series the "Gecko Structure," symbolizing its purity and dedication. The relevant patent was obtained in 2024 (Patent No.: ZL 2024 1 1365548.6).

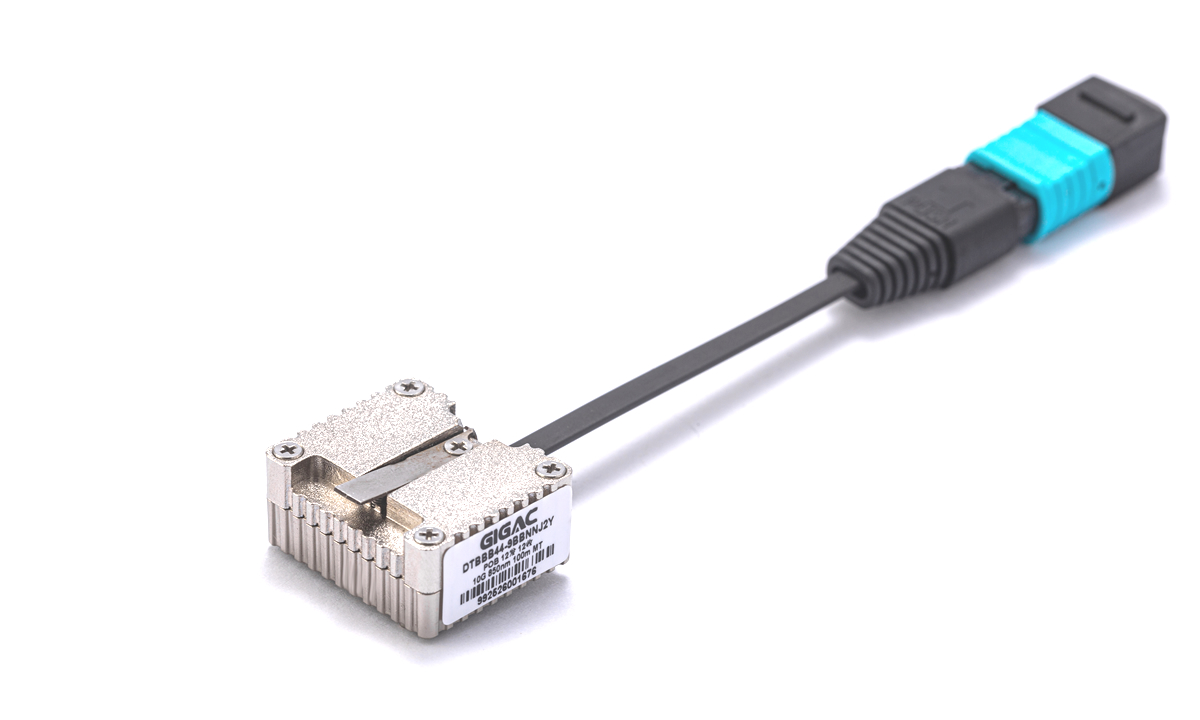

The Gecko Structure optical module, by separating the module from the fiber, offers significant advantages in flexibility, maintenance efficiency, cost control, and high-density deployment. It is particularly well-suited for modern optical communication networks with stringent requirements for bandwidth, reliability, and scalability. Its modular design aligns with the future trend of intelligent and reconfigurable optical networks.

Application Features: Reduces user concerns about fiber breakage and maintenance costs; easily standardizes parallel modules; significantly reduces the number of parallel module models; and reduces overall management costs.

Gecko Structure series product matrix:

| Series | Channel Configuration | Rate Range | compatibility |

| LCC Parallel optical transceivers | 4aisle、8aisle、12aisle | 155M-25G | Fully compatible with pigtail fixed type |

| POB Parallel optical transceivers | 4aisle、8aisle、12aisle、24aisle | 155M-25G | Fully compatible with pigtail fixed type |

Comparison of full life cycle cost optimization for Gecko Structure series optical modules:

| Stage | Traditional Solution | Gecko Structure | Improved efficiency |

| Procurement Period | Multiple Model Purchases | Single Model Purchases | Cost reduction >20% |

| Operation and Maintenance Period | Entire Module Replacement | Fiber Replacement | Expense reduction >80% |

| Inventory Period | Multiple Models in Stock | Standard Modules + Multiple Patch Cords | Turnover rate increase >300% |

Typical Application Cases of the Gecko Structure:

Retrofit Comparison of a Shipborne Command System

Original System: 32 Optical Module Models, Average Annual Maintenance Cost of 830,000 RMB

Retrofit: 4 Gecko Structure POB Modules + 12 Patch Cords, First-Year Overall Cost Reduction of 21%

Key Parameter: System MTBF Increased from 12,000 to 28,000 Hours

Core Parameters of the Gecko Structure Series Products:

Optoelectronic Performance:

- Extinction Ratio: ≥3dB (25Gbps@25°C)

- Receiver Sensitivity: ≤-10dBm (BER=1E-12)

- Dynamic Power Range: ±2dB (Full Temperature Range)

Mechanical Characteristics:

- Plug-in/Remove Life: ≥500 Cycles (Compliant with IEC 61753-1 Standard)

- Tensile Strength: >15N (Fiber Interface Axis)

Environmental Adaptability:

- Operating Temperature: -40°C to +85°C

- Storage Temperature: -55°C to +125°C

- Protection Level: IP67 (dustproof and waterproof)

Vibration and shock test data based on aerospace standards

1. Reliability Test Data:

| Test Items | Standard Reference | Test Conditions | Acceptance Results |

| Vibration Test | GJB150.16A | Triaxial Random Vibration >5-2000Hz/0.2g²/Hz | No structural deformation Zero bit error rate degradation |

| Impact Test | GJB150.18A | 20g/11m Three-dimensional six-axis impact | Gold finger displacement<5μm |

| Temperature Cycle Test | GJB548B | -55℃↔125 >48 cycles | Parameter drift<0.1dB |

| Salt spray corrosion | MIL-STD-810G | 5%NaCl solution >96 hours | Contact resistance change<3% |

2. Extreme Environment Test Data:

- High Temperature Aging: 85°C/3000 hours, optical power attenuation <0.05dB

- Low Temperature Startup: -40°C cold start time 2.1 seconds (GJB requirement ≤3.5 seconds)

- Damp Heat Test: 85°C/85% RH, 168 hours, insulation resistance >100MΩ

Open the file below to view the test report:

Gecko Structure LCC48 4T4R Vibration and Shock Test Report

Gecko Structure POB 12T12R Vibration and Shock Test Report

Background on the Development of GigacF Technology's Gecko Structure Parallel Optical Modules:

In modern defense equipment systems, optical modules are core components for high-speed data transmission. Their reliability, compatibility, and maintenance efficiency directly impact operational effectiveness. Addressing the five major industry pain points of traditional parallel optical modules:

Model redundancy: Fiber length discrepancies lead to a surge in SKUs (typically, managing over 20 models).

Inefficient maintenance: A fiber break requires complete module replacement (industry average scrap rate >35%).

Inventory pressure: Stocking modules with multiple fiber lengths occupies warehouse resources (inventory turnover rate <1.2 times/year).

Delivery delays: Customized production cycles can take up to 6-8 weeks.

Unified model dilemma: Insufficient cross-system device interface compatibility.

Facing these industry pain points, Gigac Technology, leveraging its deep technical expertise and innovative spirit, forged a new path. Inspired by the remarkable regeneration of geckos' tails, the R&D team boldly proposed the innovative concept of separating parallel modules from optical fibers. After two years of arduous R&D and millions of dollars in investment, they successfully launched the "Gecko Structure" series of optical modules, featuring separate parallel modules and pigtails.

The Gecko Structure, the purest of the nine dragon sons in ancient Chinese mythology, symbolizes innocence and focus. The project leader named the product after this, signifying the product series's unwavering pursuit of excellence. Notably, this product series received patent certification in 2024 (patent number: ZL 2024 1 1365548.6), demonstrating Gigac Technology's strong technical capabilities and innovative value in the optical communications field.