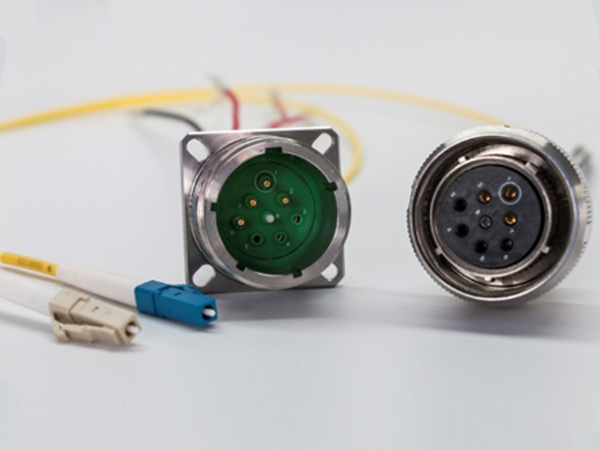

The J599I aviation plug is a leading representative of electrical connectors, offering superior performance and widespread application, providing reliable electrical connections for a wide range of systems. Its high-strength metal housing is vibration- and impact-resistant, ensuring stable connections and preventing loosening and damage in harsh mechanical environments such as aerospace, military, and industrial applications, ensuring continuous and reliable signal transmission. The J599I electrical connector offers excellent electrical performance and compatibility with a wide range of voltage and current levels. Its high-quality contacts, crafted with advanced technology, offer low contact resistance and high conductivity, reducing energy loss and heat generation. Its excellent insulation prevents electrical leakage and short circuits, ensuring equipment and personnel safety. The J599I electrical connector is highly adaptable to environmental conditions, offering protection against water, dust, and salt spray, and a high level of protection. It withstands corrosion in harsh environments such as marine vessels, outdoor base stations, and desert industries, providing stable and reliable performance and reducing maintenance costs and failure rates. A variety of interface types and pin counts are available to flexibly meet diverse needs.

Gigac Technology's J599 series aviation plugs are widely used in high-end fields such as aerospace, military defense, communications, industrial automation, and rail transit. They play an important role in key parts such as aircraft electrical systems, missile launches, base station equipment, industrial robot control, and high-speed rail electrical equipment interconnection. They are highly recognized and trusted, and have effectively promoted technological progress in the industry.

Product Features:

Compliant with GJB599B (MIL-DTL-38999M) Series I standard

Bayonet-style quick-connect, offering advantages such as compact size, light weight, and high contact density

Five-key circumferential identification and positioning for blind and mis-mating prevention

Housing options available in various materials and coatings to suit diverse environments

Sockets available in box, wall, front-mount, rear-mount, and nut-fastened mounting styles

Removable crimped contacts with anti-slant insertion design

Nine housing sizes and various hole and contact arrangements

High-intensity vibration resistance

Equipped with electromagnetic shielding

Mechanical Performance

• Mechanical Life

500 mating and unmating cycles

• Shock

3ms half-sine wave, 300G peak acceleration

Sinusoidal vibration, frequency 10Hz-2000Hz, acceleration 294m/s²

Random vibration, frequency 100Hz-1000Hz Power Spectral Density

1G²/Hz

Environmental Performance

• Temperature Range

Class B -65°C to +175°C

Class E and F -65°C to +200°C

• Salt Spray: Tested according to GJB1217 Method 1001

Class B 500h Class E 500h

Class F 48h

Electrical Performance

• Withstand Voltage: V

Operating Class | M | N | Ⅰ | Ⅱ |

sea level | 1300 | 1000 | 1800 | 2300 |

21000m | 800 | 600 | 1000 | 1000 |

• Insulation Resistance:

Normal conditions ≥5000MΩ

Wet conditions ≥100MΩ

• Contact Resistance and Rated Current:

Contact Specifications | Working Diameter | Contact Resistance | Rated Current |

22D | Φ0.76mm | ≤12mΩ | 5A |

20# | Φ1.00mm | ≤5mΩ | 7.5A |

16# | Φ1.60mm | ≤2.5mΩ | 13A |

12# | Φ2.40mm | ≤1.5mΩ | 23A |

10# | Φ3.15mm | ≤1.0mΩ | 40A |

EMI Shielding:

Minimum attenuation: 85dB from 100MHz to 1GHz

Minimum attenuation: 50dB from 1GHz to 10GHz

• Electrical continuity between enclosures

Class B: ≤ 2.5mΩ

Class E: ≤ 50mΩ

Class F: ≤ 1.0mΩ

Other Performance

• Relative humidity: 98% at 40°C

• Operating altitude: ≤ 30-480m

• Excellent resistance to moisture, salt spray, mildew, sand, and dust